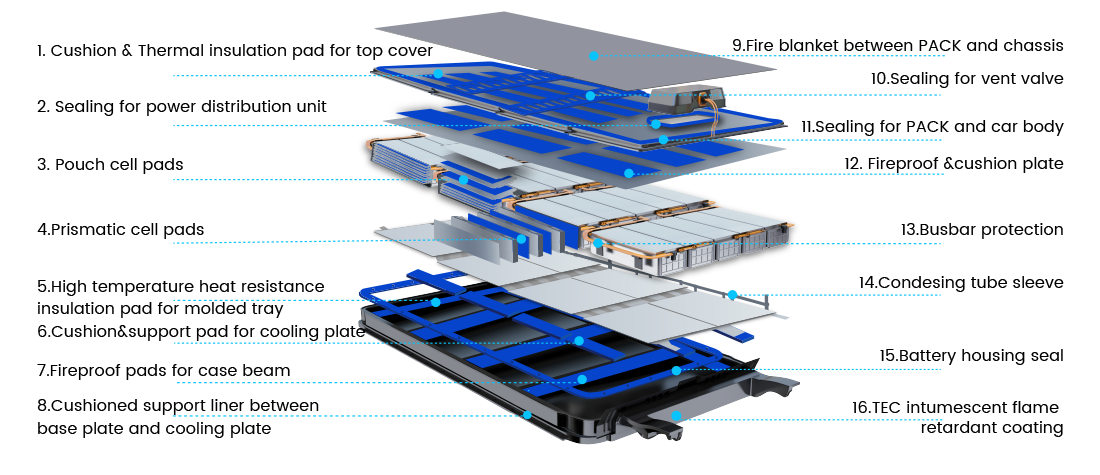

Focusing on New Energy Battery Technology And Safety Innovation: XYFOAMS Presents Ceramic-Silicone Composite Materials at InterBattery 2025

The 2025 InterBattery Exhibition in South Korea is being held this week, attracting top-tier companies, research institutions, and industry experts from the global new energy sector to explore the future of technology trends. At this exhibition, XYFOAMS is showcasing its innovative thermal runaway p

More >>

Invitation to Visit Hubei Xiangyuan Booth at InterBattery 2025 in Seoul, Korea

Dear Industry Colleagues,We cordially invite you to attend InterBattery 2025, taking place from March 5th (Wednesday) to March 7th (Friday), 2025, at the COEX Exhibition Center in Seoul, Korea. Please visit the Hubei Xiangyuan New Material Technology Inc. booth (Booth Number: B106) for an engaging e

More >>

Invitation-The International Surface Event (TISE) 2025

Xiangyuan New Materials is excited to invite you to join us at the 2025 International Floor Materials, Tiles, and Stone Exhibition in Las Vegas, USA. As one of the industry's most influential events, we understand that each gathering represents a collision of innovative ideas and inspiration, servin

More >>