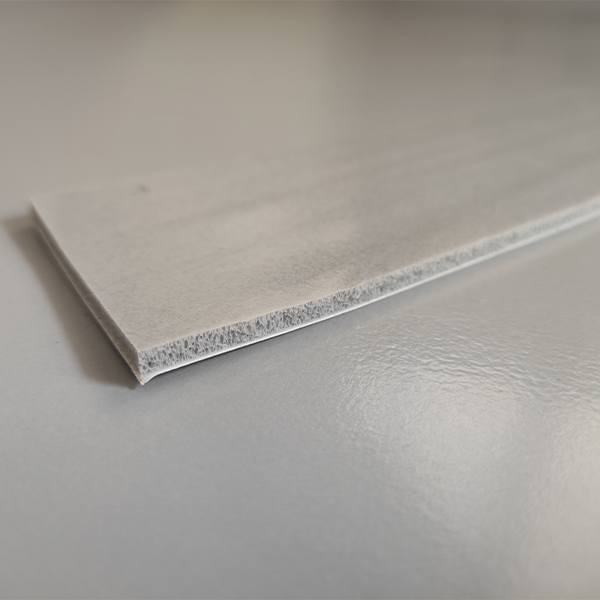

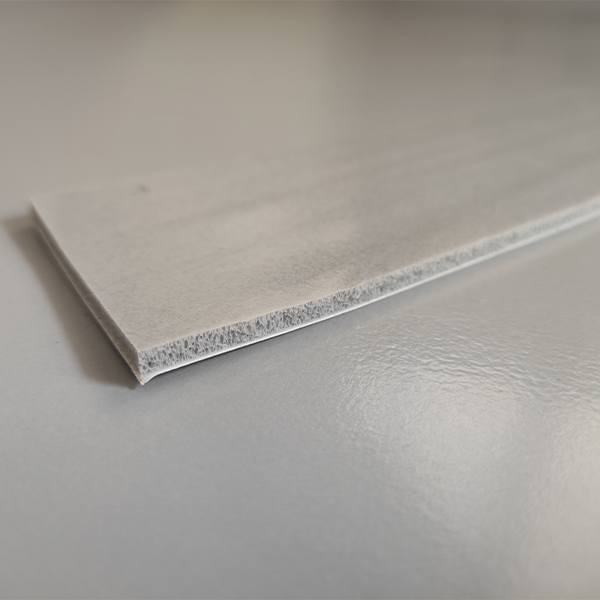

Product Characteristics:

Excellent resistance to compressive deformation

Outstanding resistance to high and low temperatures

Excellent flame retardancy, up to VO class

High oxygen index, low smoke, low toxicity

Good waterproof sealing

Product Use:

Application area:

Automotive, Railway, Aircraft, Telecom & Electrical Cabinets, Handheld Communication Devices, Outdoor Lighting, Medical Devices, Cables & Fiber Optics, Manufacturing Equipment.

Typical Applications:

Case sealing

Flexible core cushioning and insulation

Liquid Cooling Plate Support

Module/Square Cell Cushioning and Insulation

Vibration damping and cushioning for rail transportation

Performane Index

Typical Performance Parameters of Silicone Foam:

Performance

Model | densities

g/cm3 | compressive stress

@25% Kpa | tensile strength

Mpa | elongation

% | Permanent deformation in compression

(100℃) | water absorption

% | low temperature

bent | Environmental testing | Flame retardant grade | dielectric strength

KV/mm | bulk resistivity

Ω.cm | thermal conductivity

w/(m.k) |

| SSF-T20 | 0.23 | 15 | ≥200 | ≥50 | ≤5 | <5 | ‘-55℃ Qualified | RoHS Qualified | V0 | ≥2.0 | ≥1.0*1013 | 0.06 |

| SSF-T25 | 0.26 | 35 | ≥200 | ≥60 | ≤5 | <5 | ‘-55℃ Qualified | RoHS Qualified | V0 | ≥2.5 | ≥1.0*1014 | 0.06 |

| SSF-T35 | 0.37 | 75 | ≥300 | ≥60 | ≤5 | <5 | ‘-55℃ Qualified | RoHS Qualified | V0 | ≥3.0 | ≥1.0*1014 | 0.07 |

| SSF-T40 | 0.4 | 110 | ≥350 | ≥70 | ≤5 | <5 | ‘-55℃ Qualified | RoHS Qualified | V0 | ≥3.0 | ≥1.0*1014 | 0.08 |

| SSF-T50 | 0.55 | 140 | ≥700 | ≥80 | ≤5 | <5 | ‘-55℃ Qualified | RoHS Qualified | V0 | ≥4.0 | ≥1.0*1014 | 0.08 |

| SSF-T60 | 0.62 | 250 | ≥800 | ≥60 | ≤5 | <5 | ‘-55℃ Qualified | RoHS Qualified | V0 | ≥5.0 | ≥1.0*1014 | 0.08 |

Solid Silicone Gel Typical Performance Parameters:

Performance

Model | densities

g/cm3 | Tensile strength

(with glass fiber)

FMPa | hardness | electrical insulation resistance

MΩ | Withstanding voltage leakage current

mA | High-temperature insulation resistance

(800℃) | Fire performance | Environmental testing | Flame retardant grade | dielectric strength

KV/mm | bulk resistivity

Ω.cm | thermal conductivity

w/(m.k) |

| SSG-C10 | 1.2~1.7 | ≥15 | 60 | ≥1000 | ≤0.1 | ≥0.3 | not burnt through | RoHS Qualified | VTM-

0(0.3mm)

&V-

0(3.0mm) | ≥20 | ≥1.0*1014 | ≤0.5 |

| SSG-S10 | 1.2~1.7 | ≥15 | 60 | / | / | ≥0.3 | not burnt through | RoHS Qualified | VTM-

0(0.3mm)

&V-

0(3.0mm) | ≥20 | ≥1.0*1014 | ≤0.5 |

Ceramicized Silica Gel Typical Performance Parameters:

Performance

Model | densities

g/cm3 | compressive stress

@25% Kpa | tensile strength

Mpa | elongation

% | Permanent deformation in compression

(100℃) | water absorption

% | Recommended operating temperature | Environmental testing | Flame retardant grade | dielectric strength

KV/mm | thermal conductivity

w/(m.k) |

| SSG-E25 | 0.28 | 40 | ≥200 | ≥60 | ≤5 | <5 | -55~200 | RoHS Qualified | V0 | ≥3.0 | 0.07 |

| SSG-E40 | 0.4 | 65 | ≥300 | ≥60 | ≤5 | <5 | -55~200 | RoHS Qualified | V0 | ≥3.0 | 0.07 |

| SSG-E45 | 0.45 | 120 | ≥300 | ≥60 | ≤5 | <5 | -55~200 | RoHS Qualified | V0 | ≥3.0 | 0.07 |

| SSG-E49 | 0.52 | 170 | ≥300 | ≥60 | ≤5 | <5 | -55~200 | RoHS Qualified | V0 | ≥3.0 | 0.07 |

Product Specification

Foamed Silicone Sheet Packing Specification Table (T/H Series):

| Material Thickness Specification(mm) | Packaging meters(m/Volume) | width(mm) | Number of control fittings | specification category | Packaging Style |

| 0.8≤T≤1 | 100 | 400/500 | 5 | General specifications | BZSI003 |

| 900/914 | BZSI004 |

| 90 | 400/500 | 5 | Non-usual specifications | BZSI003 |

| 900/914 | BZSI004 |

| 80 | 400/500 | 4 | Non-usual specifications | BZSI003 |

| 900/914 | BZSI004 |

| 70 | 400/500 | 4 | Non-usual specifications | BZSI003 |

| 900/914 | BZSI004 |

| 60 | 400/500 | 3 | Non-usual specifications | BZSI001 |

| 900/914 | BZSI002 |

| 50 | 400/500 | 3 | General specifications | BZSI001 |

| 900/914 | BZSI002 |

| 1<T≤3 | 50 | 400/500 | 3 | Non-usual specifications | BZSI003 |

| 900/914 | BZSI004 |

| 40 | 400/500 | 2 | Non-usual specifications | BZSI003

BZSI004 |

| 900/914 |

| 30 | 400/500 | 2 | Non-usual specifications | BZSI003 |

| 900/914 | BZSI004 |

| 20 | 400/500

900/914 | 1 | General specifications | BZSI001 |

| 900/914 | BZSI002 |

| 10 | 400/500 | 1 | Non-usual specifications | BZSI001 |

| 900/914 | BZSI002 |

| 3<T≤6 | 40 | 400/500 | 2 | Non-usual specifications | BZSI005 |

| 900/914 | BZSI006 |

| 30 | 400/500 | 2 | Non-usual specifications | BZSI005 |

| 900/914 | BZSI006 |

| 20 | 400/500 | 1 | General specifications | BZSI003 |

| 900/914 | BZSI004 |

| 10 | 400/500 | 1 | Non-usual specifications | BZSI001 |

| 900/914 | BZSI002 |

| 6<T≤8 | 30 | 400/500 | 2 | Non-usual specifications | BZSI005 |

| 900/914 | BZSI006 |

| 20 | 400/500 | 1 | General specifications | BZSI003 |

| 900/914 | BZSI004 |

| 10 | 400/500 | 1 | Non-usual specifications | BZSI003 |

| 900/914 | BZSI004 |

| 8< T≤12 | 20 | 400/500 | 1 | General specifications | BZSI005

BZSI006 |

| 900/914 |

| 10 | 400/500 | 1 | Non-usual specifications | BZSI003 |

| 900/914 | BZSI004 |

Foamed Silicone Sheet Packing Specification Sheet (C Series):

| Material Thickness Specification(mm) | Packaging meters(m/Volume) | width(mm) | volume diameter(mm) | Packaging Style |

| 0.2/0.25 | 50 | 400/500 | 141 | BZSI007 |

| 900/1000 | BZSI008 |

| 100 | 400/500 | 180 | BZSI007 |

| 900/1000 | BZSI008 |

| 0.3 | 50 | 400/500 | 162 | BZSI007 |

| 900/1000 | BZSI008 |

| 100 | 400/500 | 213 | BZSI001 |

| 900/1000 | BZSI009 |

| 0.5 | 50 | 400/500 | 198 | BZSI001 |

| 900/1000 | BZSI009 |

| 100 | 400/500 | 266 | BZSI001 |

| 900/1000 | BZSI009 |

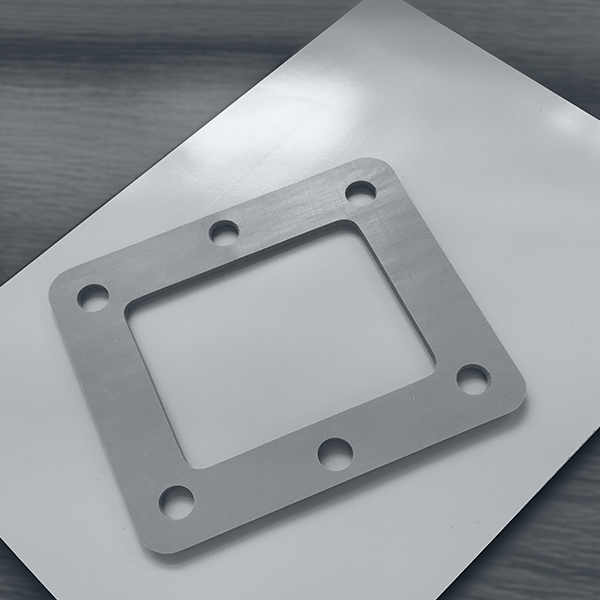

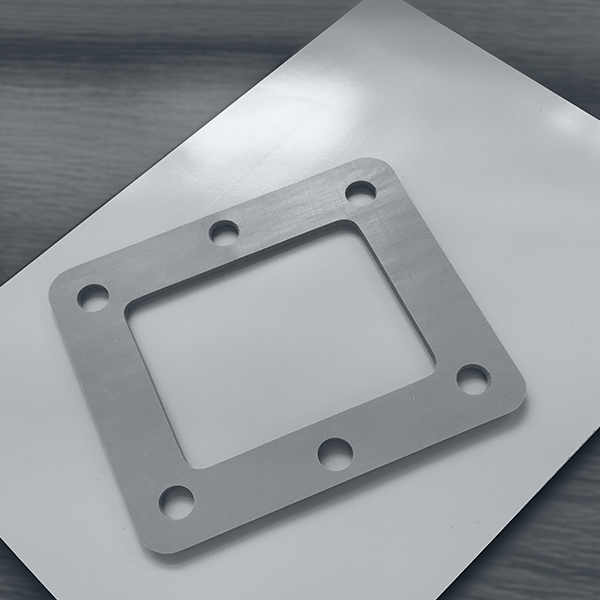

Processing services:

Rubber backing

Silicone double-sided adhesive, acrylic double-sided adhesive, single-sided adhesive, etc.

Material Slitting

Minimum slitting width 3mm, can slit double-sided adhesive, single-sided adhesive, protective film, release film, release paper, PET, etc., material roll diameter is commonly used 3 inches, 6 inches.

Customized Product

The company can provide customized service of special specification products according to the needs of customers.