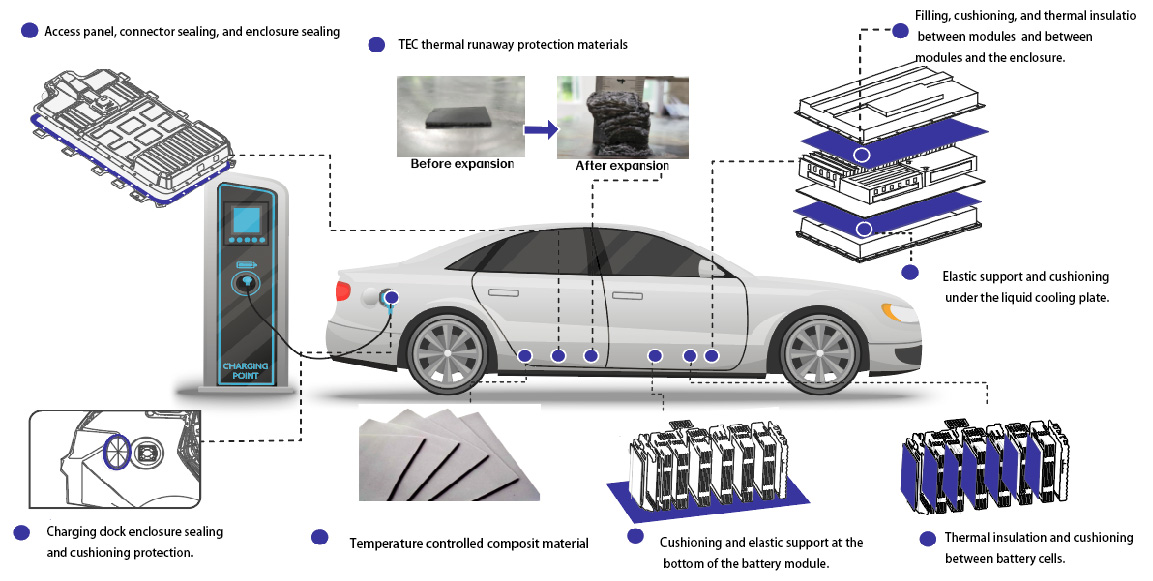

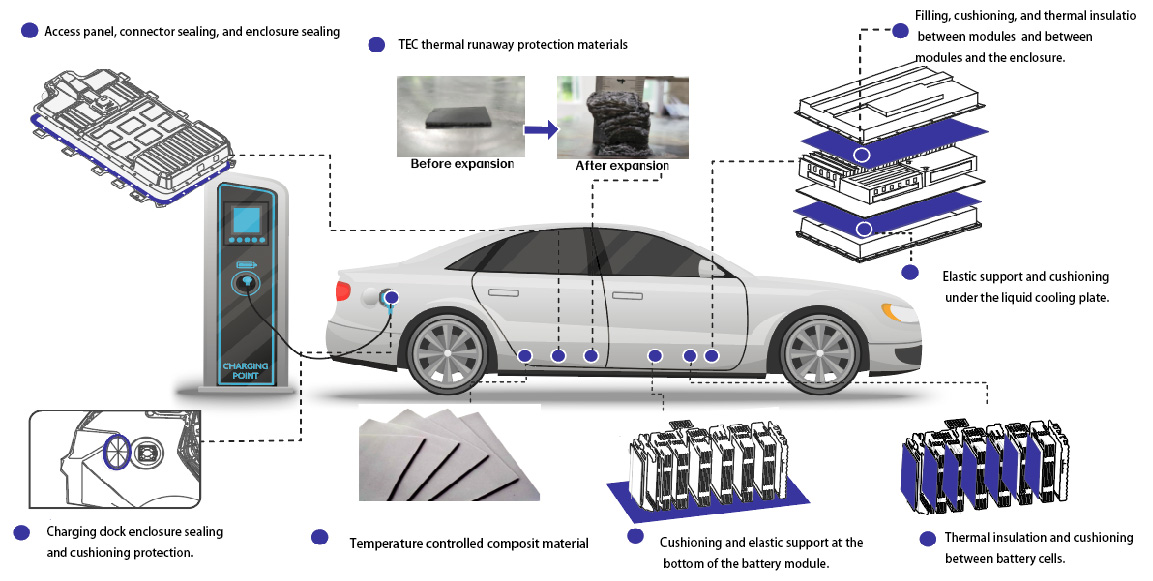

Our foam materials are used for filling, insulation, and cushioning between battery modules and inside the enclosure, providing reliable elastic support and temperature control. Especially during thermal runaway of the battery, they play a critical protective role. Additionally, the foam materials enhance sealing and safety at the charging port and other key areas, offering comprehensive protection for the safety and performance of electric vehicles.

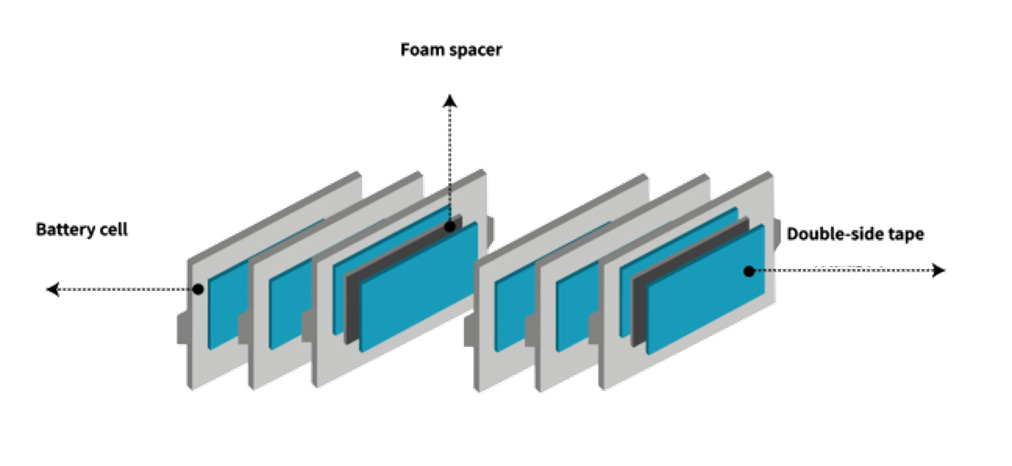

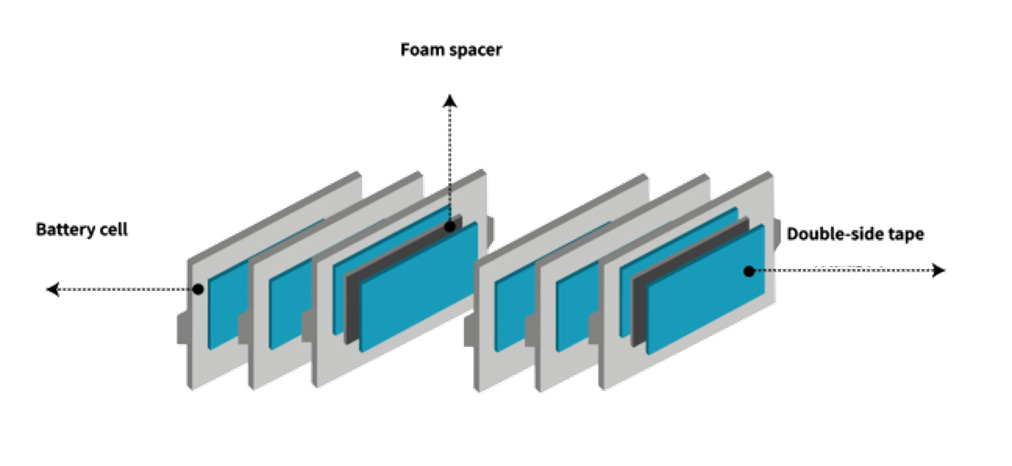

Cushioning and insulation materials between pouch cells

Recommended materials: INF series flame-retardant polyurethane microporous foam, SSF series silicone foam, DEF series polyolefin foam materials

Features: The foam has the characteristics of low hardness and high resilience, which can absorb the swelling stress of the cells to the maximum extent and prevent safety accidents caused by cell expansion. If one cell experiences thermal runaway, it can directly affect adjacent cells and intensify the severity of thermal runaway. At this point, the foam between the cells can provide excellent thermal insulation, suppress heat diffusion, and reduce the likelihood of accidents. In the event of a cell fire, the flame-retardant properties of the foam can delay the spread of the fire, increasing escape time. The foam also has excellent resilience, with a wide compression range and adjustable pre-warning force, allowing it to accommodate dimensional tolerances of the cells.

Cushioning & Insulation Materials for Modules and Prismatic Cells

Recommended materials: INF series flame-retardant polyurethane microporous foam, SSF series silicone foam, DPF/DEF series polyolefin foam materials

Features: The foam can be used alone through die-cutting or laminated with aerogel, mica sheets, etc., to maximize functionality. It has the characteristics of low hardness and high resilience, which can absorb the swelling stress of the cells to the greatest extent. Additionally, it can accommodate the dimensional tolerances of components like aerogel and prismatic cells. The compression stress of the material can be adjusted according to customer-specific pre-warning force requirements. There are multiple material solutions available, tailored to meet various demands such as maximum compression, cost efficiency, and flame retardancy.

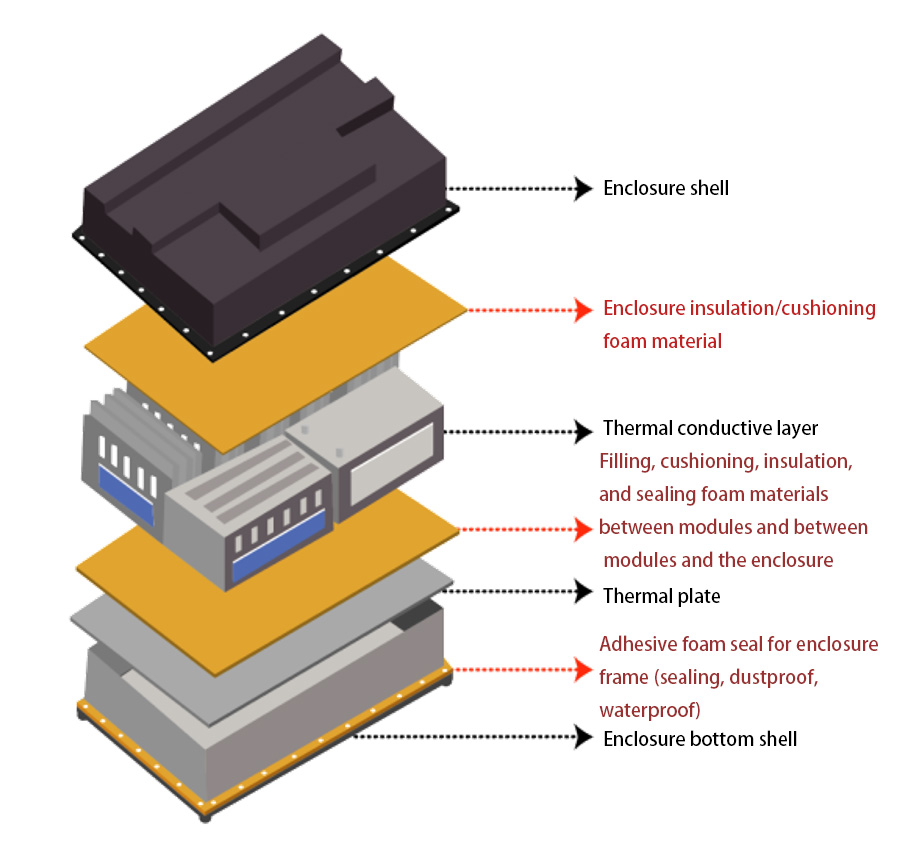

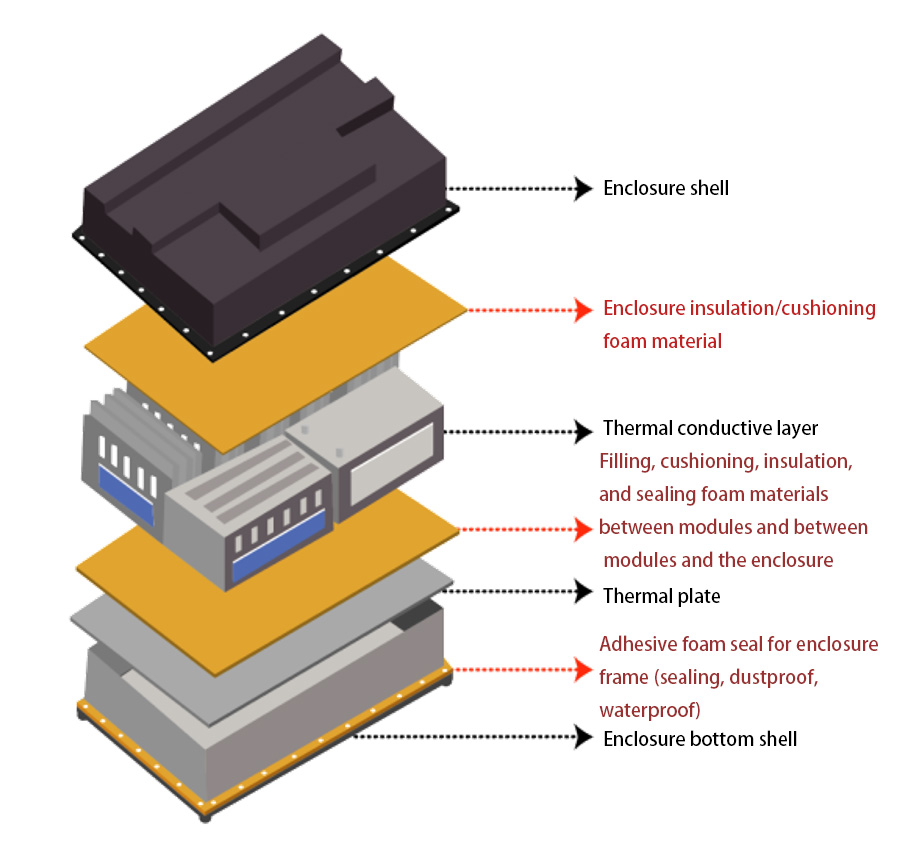

Insulation & Filling for Modules and Battery Enclosures

Recommended Materials: INF series flame-retardant polyurethane microporous foam, SSF series silicone foam, DPF/DZF/DCF series polyolefin foam materials

Features: In low-temperature environments, the energy and power characteristics of lithium-ion power batteries significantly degrade. To improve the low-temperature performance of power batteries, insulation and heating are required. Xiangyuan New Materials offers a wide range of insulation and filling material solutions tailored for various application scenarios and requirements inside and outside the enclosure, and between modules. These materials are selected based on factors such as temperature resistance, flame retardancy, insulation, breathability, water absorption, resistance to acids and alkalis, compressibility, compression stress, thermal conductivity, and weight. The materials can be widely applied inside the battery pack at the module level as well as on the exterior of the enclosure.

More relevant information:

Thermal insulation solutions for battery pack

Cushion& Thermal Insulation Material for module, prismatic call battery

New Energy Power Battery - Cushion & Thermal Insulation Pad between Cells

New Energy Power Battery - Frame Sealing

Module Thermal Insulation Material For NEV

Charging Station