Sealing and Waterproof Foam Product Introduction

Xiangyuan Polyurethane USF-WP Foam is a specially designed low-density waterproof polyurethane foam, created to offer an economical solution for sealing light, air, and moisture with excellent sealing performance. It also features good compressibility and resistance to deformation, making it suitable for irregular products. It only requires 50% compression to achieve efficient sealing and can be used in various environmental and temperature conditions. USF-WP Foam is free from plasticizers, minimizing the risk of damaging other materials it contacts. Additionally, it is an eco-friendly product with advantages such as low odor, low VOC, low misting, and halogen-free properties. It is available in different thicknesses to meet the performance requirements of various applications.

Product Features:

Only requires 50% compression to effectively seal water, dust, and air

Maintains stable waterproofing even under low compression conditions.

Low Odor, Low VOC, Low Misting, Halogen-Free

Dimensionally Stable Under Compression, Quick Rebound After Compression

Plasticizer-Free, No Leaching, Does Not Damage Contact Materials

Easy to Compress, Adapts to Any Curves and Irregular Shapes

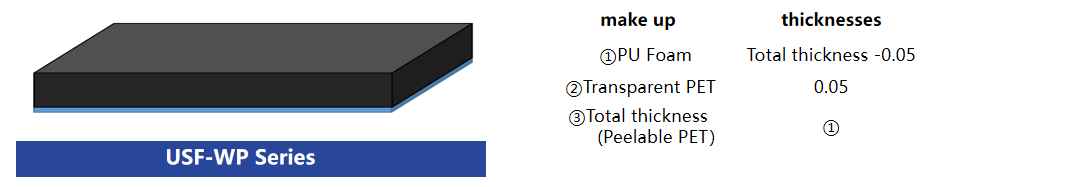

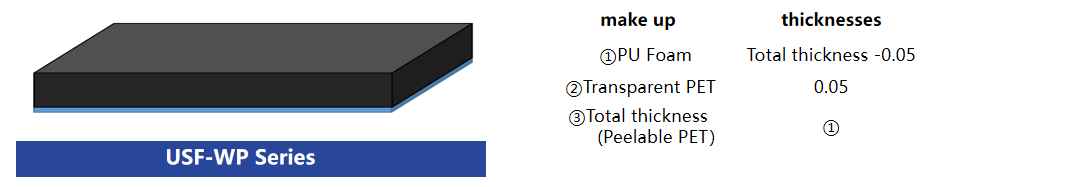

Dual-skin structure

Sealing and Waterproof Foam Product Information

Item | Unit | Values | Test Method |

Thickness Tolerance | mm | 3~10 | Thickness Gauge |

±10% |

Density Tolerance | kg/m3 | 60 | ASTM D3574 |

±20 |

Compression Strength(25% Deflection) | Kpa | 10 | ASTM D3574 |

Compression Strength(25% Deflection) | Kpa | 18 | ASTM D3574 |

Compression Set,after 24 hour recovery | % | <10 | ASTM D3574 |

Water tightness at 50% compression | Kpa/24h | 0.98 | Internal method (U-tight water test) |

Recommended Constant Use,max | ℃ | 70 | / |

Recommended Intermittent Use,max | ℃ | 120 | / |

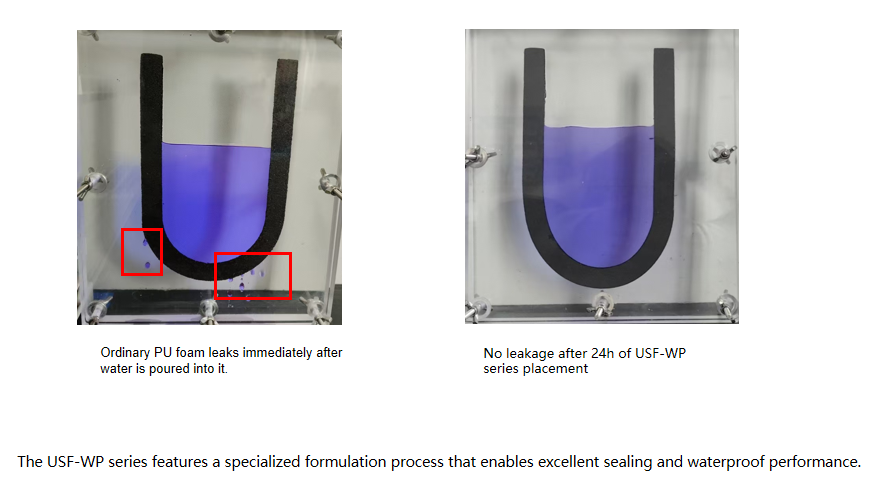

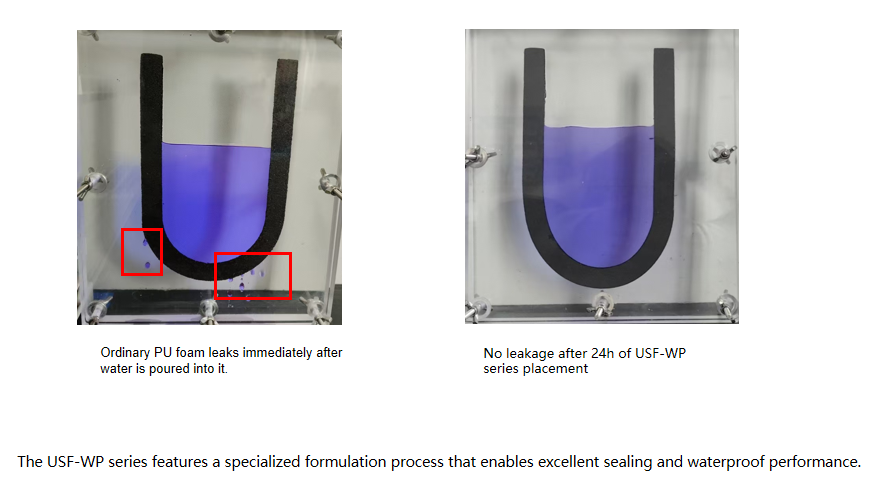

Sealing and Waterproof effect:

1.Cut the sample into a U-shape using a stamping tool.

2.Compress the sample to 50% of its original thickness and secure it with bolts and nuts. Pour water into the U-shaped sample placed between the acrylic plates (water pressure: 0.98 kPa, water height: 100 mm). Inspect whether there is any water leakage inside the sample or between the sample and the acrylic plates.

Sealing and Waterproof Foam Product Applications

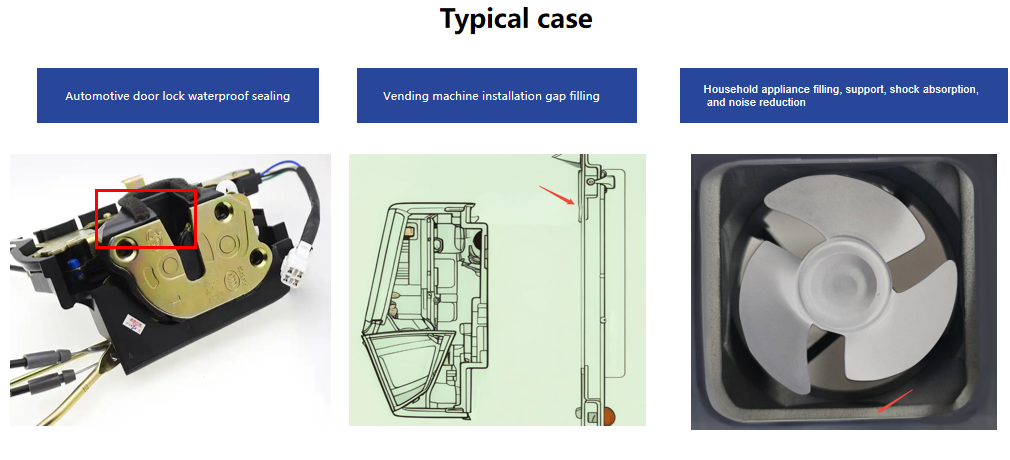

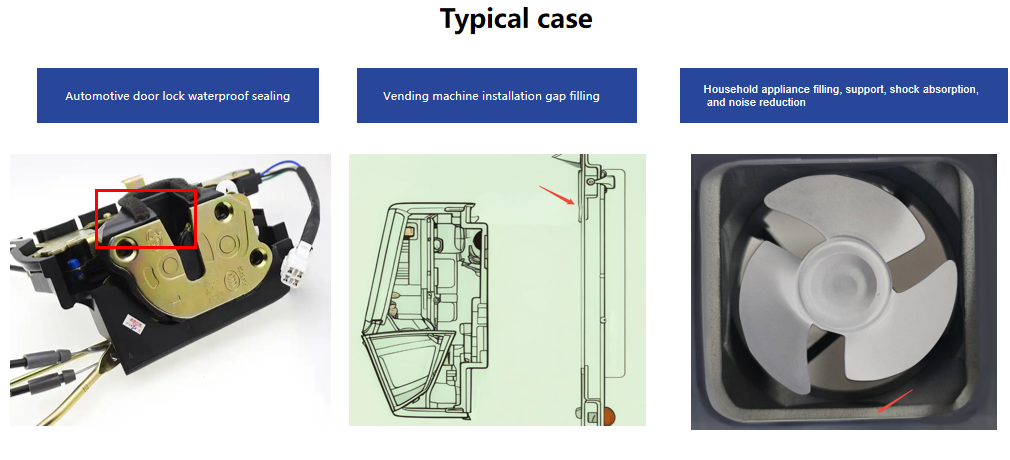

This polyurethane foam waterproof sealing material, which can be used for various applications such as waterproofing, sealing, shock absorption, sound insulation, and cushioning, is suitable for specialized fields like automotive, electric motors, construction, and civil engineering. The material is soft and easily restores its original state, with a high compression ratio and excellent conformability. It provides minimal rebound force while maintaining stable waterproof performance. Durability and environmental friendliness are also among its key features.

Sealing and Waterproof Foam Product Applications

Other applications