In recent years, the demand for high-performance materials has been on the rise, and polypropylene (PP) foam has emerged as a standout material due to its exceptional properties and versatile applications. Utilizing advanced supercritical carbon dioxide foaming technology, PP foam achieves the perfect balance between lightweight design, high strength, and environmental sustainability. Its expanding use in packaging, defense, drones, and security systems is injecting new vitality into industry advancements.

Core Advantages of Polypropylene Foam

1. Low VOC and High Environmental Standards

Produced using eco-friendly processes, PP foam contains no harmful volatile organic compounds (VOCs) and complies with RoHS and REACH regulations, making it a benchmark material for green manufacturing.

2. Lightweight and High Strength

With its internal microcellular structure, PP foam significantly reduces weight while maintaining excellent structural integrity, making it an ideal solution for industries requiring lightweight materials.

3. Superior Water Resistance and Chemical Durability

The closed-cell structure effectively blocks moisture and resists chemical corrosion, ensuring reliable performance even in harsh environments.

4. Recyclable and Sustainable

As a non-crosslinked material, MPP foam (Microcellular Polypropylene Foam) is fully recyclable, aligning with the principles of sustainable development and supporting circular economy initiatives.

Innovative Applications in High-End Industries

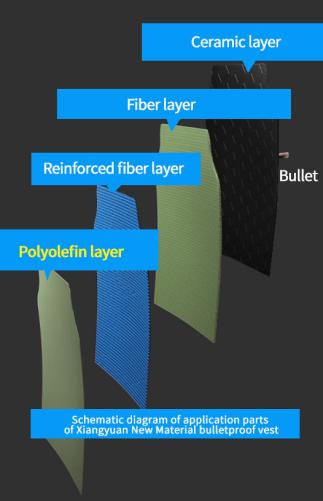

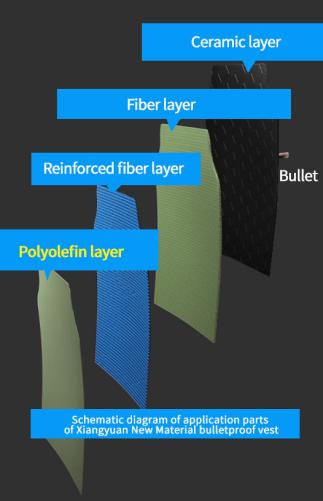

1. Defense Industry: The Ideal Material for Impact Resistance and Environmental Durability

Widely used in ballistic vest padding and protective packaging for high-value equipment.

Exceptional cushioning and impact resistance ensure reliable protection, while low-density properties enhance the portability of tactical gear.

Chemical resistance and weather durability provide stability in extreme environments.

2. Packaging Industry: Safeguarding Precision Equipment

Lightweight design and superior cushioning make PP foam a preferred choice for high-end packaging.

Extensively used for electronic devices, medical equipment, and premium consumer goods.

Customizable shapes improve packaging efficiency, reducing transportation weight and costs.

3. Drone Industry: A Dual Guarantee of Lightweight Design and Safety

High strength and low weight make PP foam ideal for cushioning pads, thermal insulation layers, and equipment packaging in drones.

Enhances energy efficiency and safety while meeting stringent environmental and health standards in the aerospace sector.

4. Cold Chain Transport: Efficient Insulation and Preservation

Closed-cell structure blocks thermal conduction, ensuring temperature stability during transport.

Preserves the quality of goods such as food and pharmaceuticals in cold chain logistics.

Future Development and Potential Applications

Electric Vehicles

PP foam can be utilized for battery pack base cushioning and module side panel protection, enhancing safety and efficiency.

Model Aviation

Lightweight design and plasticity make PP foam an ideal material for model aviation, supporting both performance and structural integrity.

Advanced Manufacturing

As production processes improve, the performance and environmental attributes of PP foam will be further enhanced, unlocking new possibilities in power batteries, security systems, and high-end packaging.

Conclusion

With its outstanding performance and environmental advantages, PP foam is reshaping material applications across industries. From high-end packaging and defense to groundbreaking uses in aerospace and electric vehicles, this material demonstrates limitless potential for innovation. As market demands evolve, the application prospects for PP foam will continue to expand, enabling industries to achieve sustainable and efficient development goals.