In today's era of rapid industrial and technological advancement, the demands for sealing technology are becoming increasingly sophisticated. From new energy vehicles to photovoltaics, rail transit, and aerospace, materials must offer superior sealing performance while balancing flexibility and strength. Silicone foam and microcellular polyurethane foam, with their unique material properties, are leading the charge in high-end sealing solutions, becoming trusted choices across various industries.

Silicone Foam: A Benchmark for High-Performance Sealing Materials

Silicone foam combines the high elasticity of silicone rubber with the multifunctionality of foam materials, making it stand out in complex industrial applications with its exceptional resistance to extreme temperatures and outstanding flexibility.

1. Reliability in High-Temperature and Extreme Environments

Silicone foam operates reliably within a temperature range of -60°C to +200°C, making it an ideal sealing material for high-temperature equipment, electronic components, and battery systems in new energy vehicles. Whether in extreme weather conditions or high-temperature operating environments, silicone foam maintains its structural integrity and performance stability.

2. Excellent Compression Set Resistance

Silicone foam exhibits an exceptionally low compression set, meaning it retains its sealing effectiveness over extended use, preventing seal failure caused by material fatigue.

3. Superior Fire Resistance and Flame Retardancy

Equipped with advanced flame-retardant systems, silicone foam meets UL94 V-0 flame-retardant standards and features low-smoke, non-toxic properties, making it particularly suitable for applications in battery packs for electric vehicles, rail transit, and electronic devices where fire safety is paramount.

4. Balance of Flexibility and Durability

The softness of silicone foam ensures excellent conformability, allowing it to seal components with complex shapes effectively. It also cushions vibrations and impacts, enhancing the overall stability of the equipment.

Key Applications:

· New Energy Vehicles: Battery pack casing seals, cushioning and thermal insulation for pouch cells.

· Rail Transit: Vibration dampening and fireproof sealing.

· Consumer Electronics: Waterproof sealing for cabinets and handheld devices.

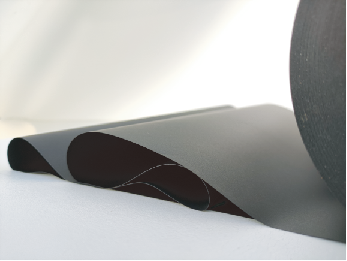

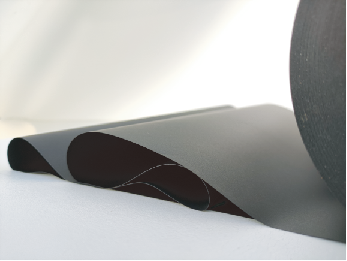

Microcellular Polyurethane Foam: A Perfect Blend of Lightness and Strength

Microcellular polyurethane foam (PU foam) features a unique semi-closed-cell structure, providing outstanding sealing and compressive performance. Its exceptional cushioning and vibration control make it a vital material in modern high-end sealing technology.

1. Exceptional Resistance to Compression Set

By precisely controlling the foam cell structure, PU foam offers excellent resistance to compression set, ensuring consistent sealing performance even after prolonged use. This makes it an ideal choice for sealing precision electronic devices and mechanical components.

2. Superior Impact Absorption and Cushioning

PU foam materials can be tailored for specific compressive strengths, delivering excellent cushioning and shock absorption to protect equipment from external impacts and mechanical vibrations, thereby extending their service life.

3. Outstanding Sealing and Conformability

The flexibility and conformability of microcellular polyurethane foam allow it to fill gaps effectively, preventing dust, moisture, and contaminants from entering equipment. This ensures stable operation of electronic components and precision parts.

4. Lightweight and Eco-Friendly Advantages

PU foam is lightweight, environmentally compliant with RoHS and REACH standards, and highly recyclable, supporting the industry's move toward sustainable development goals.

Key Applications:

· Consumer Electronics: Dust seals for camera modules, cushioning seals for speakers.

· New Energy Equipment: Thermal insulation and cushioning between battery cells, liquid cooling plate support seals.

· 3C Devices: Bottom cushioning for displays, body seals for smart devices.

Material Synergy Driving Innovation in Sealing Technology

While silicone foam and microcellular polyurethane foam have distinct structural and performance characteristics, they complement each other in high-end sealing applications. Silicone foam excels in high-temperature and high-safety scenarios, while PU foam shines with its lightweight, cushioning properties, and eco-friendly advantages, making them indispensable in industries like consumer electronics, new energy, and more.

Comparison of Advantages:

Feature | Silicone Foam | Microcellular PU Foam |

Temperature Resistance | Excellent | Good |

Flame Retardancy | Exceptional (UL94 V-0) | Customizable (V-0 series available; standard products moderately flame-retardant) |

Compression Set Resistance | Low | Low |

Sealing and Cushioning | Outstanding | Excellent |

Eco-Friendliness | RoHS, REACH, Halogen-free | RoHS, REACH-compliant |

Sealing Technology's Future

With the rapid growth of new energy vehicles, smart devices, and rail transit, the demands for sealing materials are becoming more rigorous. XY Foams' silicone foam and microcellular polyurethane foam, with their perfect balance of flexibility and strength, are at the forefront of high-end sealing solutions. Trusted by leading brands, they are the preferred choice for manufacturers aiming to achieve unparalleled reliability and performance.

In the future, as material technologies continue to evolve and eco-conscious practices gain momentum, these two advanced materials will unlock even greater potential in industrial applications, delivering safer, more reliable, and highly efficient solutions to industries worldwide.