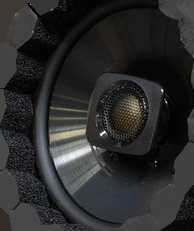

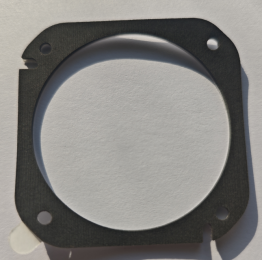

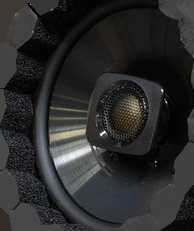

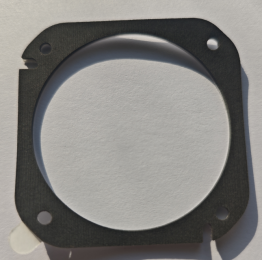

In the audio industry, optimizing sound quality often lies in the details. As a critical component, speaker gaskets combine innovative materials with precise design to enhance audio system performance. XYFOAMS' IXPE foam (irradiation cross-linked polyethylene foam) stands out as the ideal material for speaker gaskets, delivering exceptional results in soundproofing, cavity noise reduction, and noise prevention.

Advantages of IXPE Foam

Uniform Cell Structure with Independent Closed-Cell Design

Produced using electronic irradiation cross-linking technology, IXPE foam features an independent closed-cell structure. This ensures excellent sealing and compression resistance, maintaining long-term functional stability as a speaker gasket.

Outstanding Permanent Compression Set Resistance

IXPE foam exhibits a low permanent compression set, enabling it to retain its thickness and sealing properties even after prolonged use and repeated compression, ensuring stable contact between the speaker and the enclosure.

Eco-Friendly with High Performance

In addition to complying with RoHS and other environmental standards, IXPE foam boasts exceptional chemical resistance, water resistance, and aging resistance, offering users a safe, reliable, and sustainable solution.

Recommended Specifications

The Core Functions of IXPE Foam in Speaker Gaskets

Soundproofing

The sealing ability of speaker gaskets directly affects sound quality. As a connecting material between the speaker and the cavity, IXPE foam effectively prevents sound leakage, reduces energy loss, and enhances the clarity and purity of the speaker's output.

Cavity Noise Reduction

In car doors or speaker enclosures, cavity resonance and reflections can distort sound quality. With its superior soundproofing and damping properties, IXPE foam minimizes cavity noise, improving sound depth and clarity.

Noise Prevention

During speaker operation, loose installation or improper component contact can generate mechanical noise. The flexible adaptability and vibration resistance of IXPE foam ensure a snug fit between the speaker gasket and the enclosure, effectively eliminating potential noise during installation.

Compression Cushioning and Long-Term Stability

IXPE foam offers excellent compression cushioning and stress relaxation capabilities. It supports secure speaker installation while maintaining sealing effectiveness over time, preventing performance degradation.

Typical Applications

Automotive Audio Systems

In automotive doors or dashboard speaker installations, IXPE foam gaskets effectively seal gaps between the speaker and door cavity, preventing sound leakage and reducing external noise interference during driving, resulting in clearer sound quality.

Home and Professional Audio Equipment

From home smart speakers to professional stage audio and conference systems, IXPE foam gaskets minimize resonance and reflections, enhancing sound accuracy and providing richer audio output.

Consumer Electronics

In devices such as Bluetooth speakers and TV audio systems, IXPE foam improves speaker installation sealing and soundproofing, optimizing audio performance in compact devices.

Industrial and Specialized Equipment

For industrial audio systems or specialized equipment (e.g., medical devices and rail transit audio), the high strength and chemical resistance of IXPE foam meet the demanding performance requirements of these applications.

XYFOAMS’ Expertise in IXPE Foam Solutions

As a leading material for speaker gaskets, IXPE foam is easy to die-cut and highly suitable for audio system manufacturers. Leveraging advanced technology and in-depth material research, XYFOAMS provides reliable and eco-friendly IXPE foam materials for speaker gasket applications.

From automotive audio systems to home smart speakers and industrial devices, IXPE foam helps customers overcome challenges like sound leakage, cavity noise, and unwanted noise, enabling optimized sound quality and enhanced equipment performance. XYFOAMS' outstanding product quality and innovative material technology have earned widespread recognition from clients.