Product Introduction:

Flexographic printing requires maintaining consistent contact between the printing plate and the substrate, even on uneven surfaces such as corrugated cardboard. This necessitates excellent flexibility in the printing plate. Additionally, to ensure that non-printing areas do not transfer residual ink from the plate, the non-image areas of the plate must have sufficient depth to meet this requirement.

Function of Flexographic Plate Bonding Tape:

By selecting bonding tape foam with the appropriate density, precise control of printing pressure can be achieved. This allows the flexographic plate to align perfectly with the design and text, resulting in the flawless reproduction of printed patterns and an improvement in print quality.

Additionally, the bonding tape helps balance equipment vibrations and compensates for system errors, ensuring stable and high-

quality printing performance.

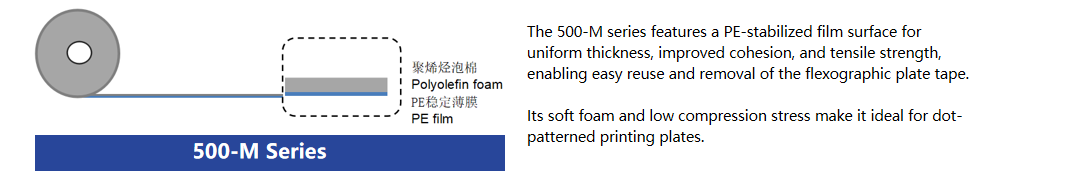

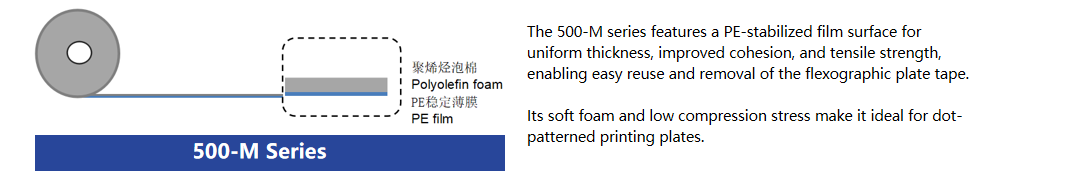

Polyolefin Foam Flexographic Tape Substrate Product Information:

Item | Unit | Values | Test Method |

Thickness Range | mm | 0.45 (0.42-0.48) | GB/T 6342 |

Expansion Rate Range | / | 4.0 (3.0-5.5) | GB/T 6342 |

Density Range | kg/m3 | 250 (181-334) | GB/T 6343 |

Color | / | White | Visual inspection |

Tensile Strength | Mpa | MD 3.5 TD 2.5 | ISO 1926 |

Elongation | % | MD 165 TD 210 | ISO 1926 |

Compression Strength(25% Deflection) | Kpa | 148 | ASTM D3574 |

Compression Strength(50% Deflection) | Kpa | 410 | ASTM D3574 |

Compression Set(25% Deflection) | ℃ | ≤10% | ASTM D3575 |

Product Information of Polyolefin Foam Flexographic Printing Tape Base Material

Item | Unit | Values | Test Method |

Thickness Range | mm | 0.3 (0.28-0.32) | GB/T 6342 |

Expansion Rate Range | / | 3.0 (1.9-4.0) | GB/T 6342 |

Density Range | kg/m3 | 333 (250-526) | GB/T 6343 |

Color | / | White | Visual inspection |

Tensile Strength | Mpa | MD 5.5 TD 4.0 | ISO 1926 |

Elongation | % | MD 300 TD 330 | ISO 1926 |

Compression Strength(25% Deflection) | Kpa | 335 | ASTM D3574 |

Compression Strength(40% Deflection) | Kpa | 570 | ASTM D3574 |

Compression Set(25% Deflection) | ℃ | ≤10% | ASTM D3575 |