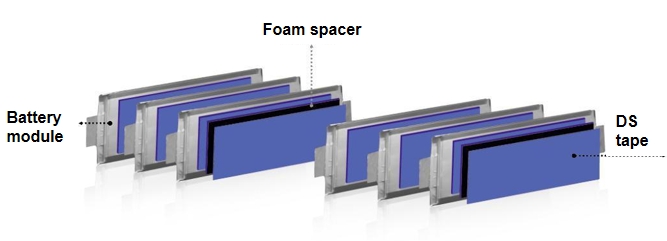

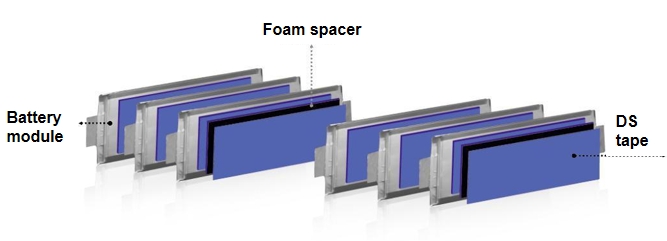

Cushion and thermal insulation foam spacer for pouch cell

Recommended materials:

INF series FR grade Polyurethane Microcellular Foam

Material Features:

1.Excellent compression set and stress relaxation properties

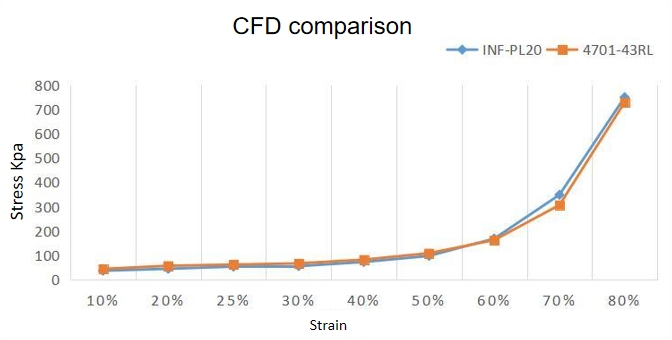

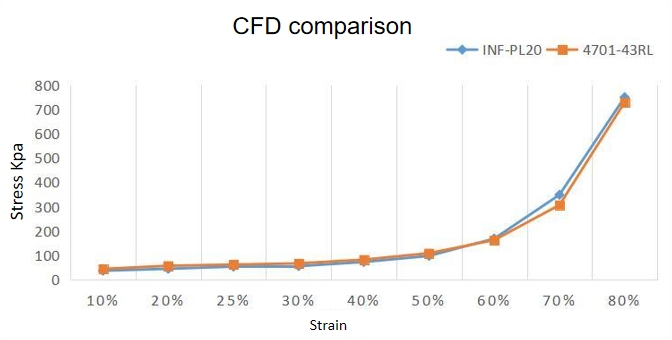

2.Customized CFD is available

3. Even foam cell, shock absorption

4.Wide operating temperature range: (-40 °C-120 °C)

5.Excellent flame retardant property

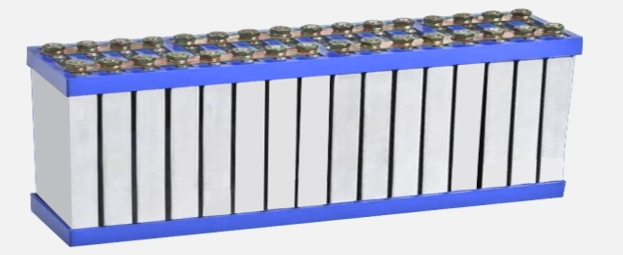

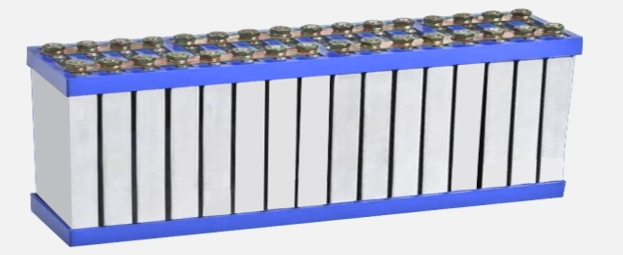

Cushion& Thermal Insulation Material for module, prismatic call battery

Recommended materials: INF series Flame Retardant Microcellular Polyurethane Foam

Features: Foam can be used directly after die-cuting, or laminating with aerogel, mica and other materials to maximize the properties of heat insulation, cushion and electric insulation. It has the characteristics of flexible hardness , high resilience , narrow dimensional tolerance and excellent compressive performance, which can fill the dimensional tolerance of aerogel, square shell and other components. Xiangyuan provides different solutions based on CFD, max. compression of cells, cost,

FR grade.

With the rapid growth of global energy demand, vigorously developing renewable energy is the future trend. Modern renewable energy technology is developing very rapidly. The cost of renewable energy decreases with the mature application of technology. Non-hydroelectric renewable energy such as wind energy, solar energy, geothermal energy, tidal energy and ocean wave energy emerge in endlessly, surpassing the global average annual growth rate of any other energy. How to efficiently store energy is the key to the development of these fields. The high-end foaming materials developed by Xiangyuan New Material can meet the requirements of new energy storage batteries for sealing and sealing materials in the future. These unique materials can effectively play the role of dust prevention, shock prevention, waterproof, flame retardant, aging resistance, and other pollutants during the use of products, reduce maintenance costs and improve energy utilization.